The Definitive Guide for Steel Road Plates

Steel layers are give a good, short-lived option for covering harmful holes on a construction website. These heavy-duty, robust plates allow roadways to go back to solution so that building can proceed. Below we check out the style details and ideal technique setup advice. These plates can be utilized to make sure that roads can still be used whilst various other phases of work continue.

They use an excellent concession for maintaining lanes, whilst work proceeds overnight and at weekends. They are frequently seen when excavations have begun as a very early phase of building and construction or repair work jobs. These plates are developed to endure sturdy usage on hectic roadways. They feature an akti-skid finishing and are available in a number of colour coatings - Steel road plates.

The weights begin with approximately 300kg and conventional road plates have a thickness of either inch or inch. We can likewise offer customised dimensions. The essential functions of the item are as complies with: Openings to permit risk-free add-on to raising plants. The capability to be bolted to the road.

Get This Report on Steel Road Plates

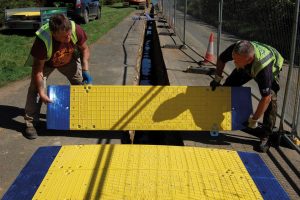

Hinged variations for quick accessibility to the excavation or regular gain access to, e.g. driveways. Composite plates, which can fit numerous lengths of trench. Skid-resistance for improved car, pedestrian and site employee security. Steel roadway plates can be installed fairly quickly, yet they are hefty. Consequently, they must be set up making use of a forklift or crane.

Look for displacement by website traffic loading from the outset plates must always resist variation. Inspect that home plates do absent a danger to any kind of kind of road individual and can be utilized by all roadway individuals and automobile types, including pedestrians, bikers and motorcyclists. Create a normal examination and maintenance to make certain that performance continues to be secure and optimum.

Take care of the plates correctly whatsoever times. Mechanical lifting guarantees that home plates are mounted precisely and safely. The ideal plates should be suitable for the preferred objective Take into consideration ideal safety zones, specifically when planning setup. The weight of home plates can cause swinging in the construction location or across neighbouring carriageways/ footways.

If a ramp is created by the road layers, then cautioning indicators for pedestrian and road customers are called for. Always a conduct complete website survey, and take the expert suggestions of a structural engineer.

5 Simple Techniques For Steel Road Plates

In order to enhance safety and security, there are a number of criteria and market papers assisting their use in construction job zones. Steel plates have to be taken care of in area to stay clear of motion.

9 Easy Facts About Steel Road Plates Explained

In addition to being firmly in call with the sidewalk, they ought to be either pinned, recessed into the sidewalk, or secured with asphalt wedges around the border. Pinning into the pavement involves driving pins into the sidewalks along the sides of the steel plates to avoid movement. Recessing involves removing the area where the steel plate will be put.

This results in the steel plate being flush with the sidewalk. Additionally, when numerous steel plates are made use of and butt approximately each other, they should be welded with each other at the longitudinal seams. Steel plates can be very unsafe, especially when they are damp, unless they have an anti-skid layer applied.

Treatment steel plates with a product that increases rubbing helps motorcyclists and bicyclists maintain control, particularly in wet climate. Find Out More Problems which minimize pavement rubbing in work zones are of certain worry to motorcyclists and bicycles. A common hazard in steel plate installations occurs when the individual falls short to construct appropriately tapered ramps from the street to the sides of the steel plate( s).

The Main Principles Of Steel Road Plates

It poses a considerable danger to motorcyclists and bicyclists who can quickly lose control when they contact the abrupt/steep tapered click to read ramp and the steel plate. Effectively conical ramps permit customers to securely go across over the steel plates.

Ensure adequate overlap. Normally, steel plates need to extend at least one foot past the sidewalk opening onto firm ground.

The Best Strategy To Use For Steel Road Plates

Welding is made use of when more than one steel plate is used and they butt up to each other. Plates should be countersunk when essential as a result of unequal roads. Plates need to be coated with an anti-skid finishing. The edges of the steel plates need to be marked/painted to boost exposure. Proper advancement caution indicators need to be made use of.

His history consists of the building and construction, inspection, find out more.

Worldwide of civil engineering and building and construction, steel roadway layers are a quintessential device that holds enormous importance. These heavy-duty steel plates play an essential role in enhancing building security, providing short-term highways, and guaranteeing smooth procedures on various project websites. As a building and construction equipment vendor, their value can not be overemphasized.